Tambaya don Mai Farashin Farashi

Don tambayoyi game da samfuranmu ko mai lissafin farashi, da fatan za a bar mana imel ɗin ku kuma za mu tuntube ku cikin awanni 24.

Siffofin injin din ...

Muhimman halaye nagilashin fiberglass da aka haɗasun haɗa da ikon mallakar fasaha mai ban mamaki da farin zare, ingantattun kaddarorin anti-static da iyawa, da kuma saurin fitar da ruwa mai kyau, da kuma ingantaccen ruwan ƙera kayan.

Tsarin gyaran takardar fiberglass (SMC) yawanci yana da ƙarfin juriya mai ƙarfi, juriya mai kyau ga tasiri, kyawawan halayen rufin lantarki, kwanciyar hankali mai girma, da juriya ga tsatsa.

Hakanan yana iya samun kyakkyawan gama saman, juriya ga zafi, da kuma ƙarfin hana harshen wuta.

| Jirgin ruwa mai haɗa fiberglass | ||

| Gilashi nau'in | Gilashin E-Glass | |

| Girman girma nau'in | Silane | |

| Na yau da kullun filament diamita (um) | 14 | |

| Na yau da kullun layi yawa (tex) | 2400 | 4800 |

| Misali | ER14-4800-442 | |

| Abu | Layi mai layi yawa bambancin | Danshi abun ciki | Girman girma abun ciki | Tauri |

| Naúrar | % | % | % | mm |

| Gwaji hanyar | ISO 1889 | ISO 3344 | ISO 1887 | ISO 3375 |

| Daidaitacce Nisa | ±5 | ≤ 0.10 | 1.05± 0.15 | 150 ± 20 |

Ba wai kawai muke samarwa bagilashin fiberglass da aka haɗakumatabarmar fiberglass, amma mu ma wakilan JUSHI ne.

· Ya fi kyau a yi amfani da samfurin cikin watanni 12 bayan an samar da shi kuma ya kamata a ajiye shi a cikin fakitin asali kafin a yi amfani da shi.

·Ya kamata a yi taka-tsantsan wajen amfani da samfurin domin hana shi karce ko lalacewa.

·Ya kamata a sanya yanayin zafin jiki da danshi na samfurin ya kasance kusa ko daidai da yanayin zafin jiki da danshi na yanayi kafin amfani, kuma ya kamata a kula da zafin jiki da danshi na yanayi yadda ya kamata yayin amfani.

·Ya kamata a riƙa kula da na'urorin yankewa da na'urorin roba akai-akai.

| Abu | naúrar | Daidaitacce | |

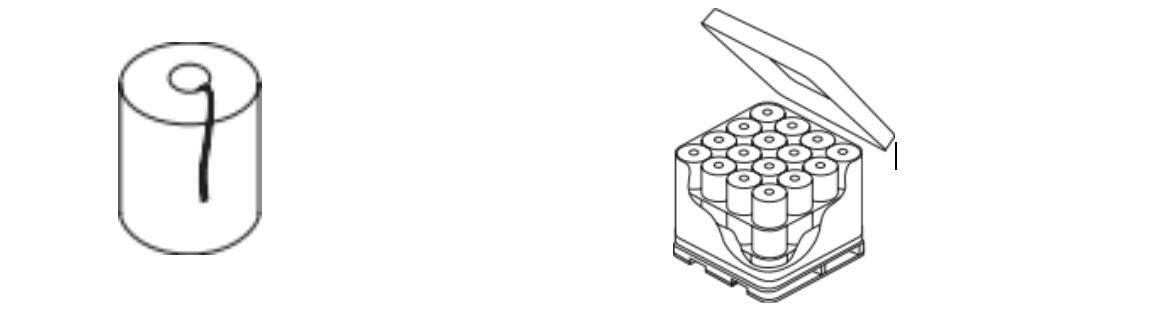

| Na yau da kullun marufi hanyar | / | An cika on fale-falen. | |

| Na yau da kullun fakiti tsayi | mm (a cikin) | 260 (10.2) | |

| Kunshin na ciki diamita | mm (a cikin) | 100 (3.9) | |

| Na yau da kullun fakiti na waje diamita | mm (a cikin) | 280 (11.0) | |

| Na yau da kullun fakiti nauyi | kg (lb) | 17.5 (38.6) | |

| Lamba na yadudduka | (Layi) | 3 | 4 |

| Lamba of fakiti kowace Layer | 个(kwamfutoci) | 16 | |

| Lamba of fakiti kowace faletin | 个(kwamfutoci) | 48 | 64 |

| Net nauyi kowace faletin | kg (lb) | 840 (1851.9) | 1120 (2469.2) |

| Faletin tsawon | mm (a cikin) | 1140 (44.9) | |

| Faletin faɗi | mm (a cikin) | 1140 (44.9) | |

| Faletin tsayi | mm (a cikin) | 940 (37.0) | 1200 (47.2) |

Ana amfani da SMC roving a fannin kera sassa daban-daban a masana'antu kamar su mota, sararin samaniya, gini, da lantarki. Sau da yawa ana amfani da shi don samar da sassa masu siffofi masu rikitarwa da buƙatun ƙarfi mai yawa, kamar bangarorin jikin motoci, wuraren rufe wutar lantarki, da sassan gini a cikin gini. Bugu da ƙari, ana iya amfani da SMC roving wajen samar da kayayyakin masarufi, kayayyakin ruwa, da sauran aikace-aikacen masana'antu waɗanda ke buƙatar kayan aiki masu ɗorewa, masu sauƙi, da juriya ga tsatsa.

Don tambayoyi game da samfuranmu ko mai lissafin farashi, da fatan za a bar mana imel ɗin ku kuma za mu tuntube ku cikin awanni 24.