Gabatarwa

Fiberglass rovingabu ne mai mahimmanci a cikin kera kayan haɗin gwiwa, yana ba da ƙarfi mai ƙarfi, sassauci, da juriya ga tsatsa. Duk da haka, zaɓi tsakaninyawo kai tsayekumatattaro jiragen ruwazai iya yin tasiri sosai ga aikin samfur, farashi, da ingancin samarwa.

Wannan jagorar tana kwatanta nau'ikan biyu, tana duba hanyoyin kera su, halayen injina, aikace-aikace, da kuma ingancin farashi don taimaka muku yin zaɓi mafi kyau ga aikinku.

Menene Fiberglass Roving?

Fiberglass roving ya ƙunshi zare-zaren gilashi masu ci gaba da aka haɗa tare don ƙarfafawa a cikin haɗakar abubuwa. Ana amfani da shi sosai a cikin:

Naɗewar Pultrusion & filament

Ma'adanin gyaran takarda (SMC)

Jakunkunan jirgin ruwa da sassan mota

Ruwan injin turbin iska

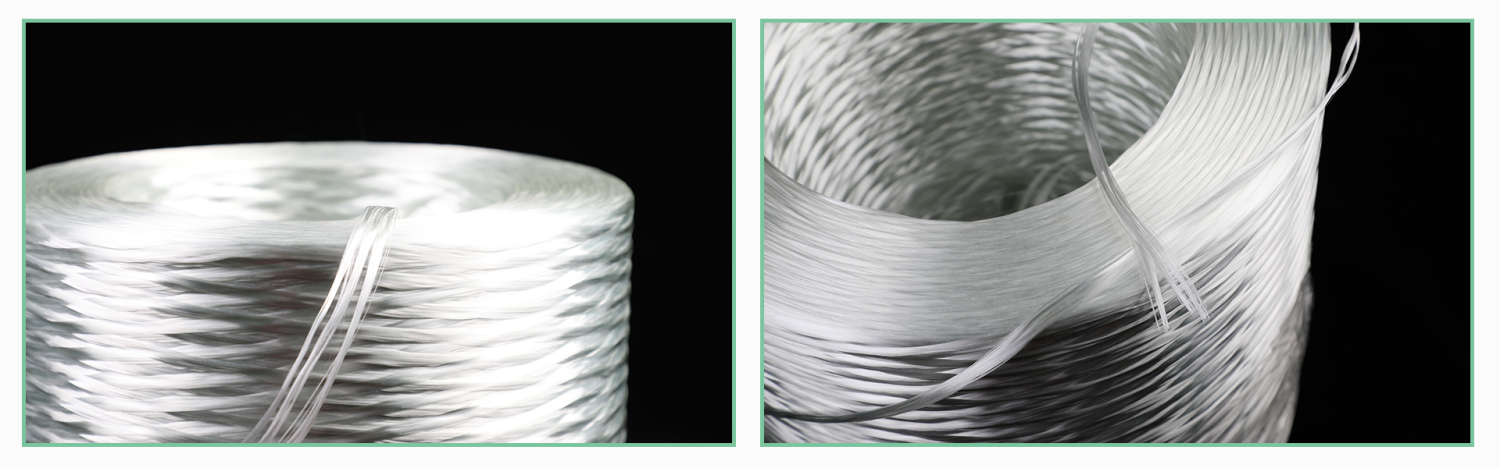

Fiberglass ryin ovingyana zuwa a cikin manyan siffofi guda biyu:yawo kai tsayekumatattaro jiragen ruwa, kowannensu yana da fa'idodi daban-daban.

Jirgin Ruwa Kai Tsaye: Siffofi da Amfani

Tsarin Masana'antu

Fiberglass dzirga-zirgar jiragen samaAna samar da shi ta hanyar zana gilashin da aka narke kai tsaye cikin zare, sannan a naɗe shi cikin fakiti ba tare da murɗewa ba. Wannan hanyar tana tabbatar da:

✔ Ƙarfin juriya mai ƙarfi (saboda ƙarancin lalacewar filament)

✔ Ingantaccen daidaiton resin (jika mai kama da juna)

✔ Ingancin farashi (ƙarancin matakai na sarrafawa)

Muhimman Fa'idodi

Manyan kaddarorin injiniya -Ya dace da aikace-aikacen matsanancin damuwa kamar jiragen sama da jiragen ruwa masu matsin lamba.

Saurin samarwa da sauri -An fi so a cikin ayyukan atomatik kamar pultrusion.

Ƙarancin samar da fuzz -Yana rage lalacewar kayan aiki a cikin ƙera.

Aikace-aikace na gama gari

Bayanan martaba masu ƙarfi (fiberglass bim, sanduna)

Tankunan da bututun da aka yi wa rauni

Maɓuɓɓugan ganye na mota

Haɗa Roving: Siffofi da Amfani

Tsarin Masana'antu

Fiberglass atattarowa ana yin sa ne ta hanyar tattara ƙananan igiyoyi da yawa da haɗa su wuri ɗaya. Wannan tsari yana ba da damar:

✔ Ingantaccen iko akan ingancin zare

✔ Ingantaccen sarrafawa a cikin hanyoyin hannu

✔ Ƙarin sassauci a rarraba nauyi

Muhimman Fa'idodi

Ya fi sauƙi a yanke da riƙewa -An fi so don yin amfani da hannu da feshi.

Mafi kyau ga siffofi masu rikitarwa -Ana amfani da shi a cikin kwale-kwale da kuma gyaran baho.

Ƙarancin farashi don ƙananan samarwa -Ya dace da bita tare da ƙarancin sarrafa kansa.

Aikace-aikace na gama gari

Gina jirgin ruwa da haɗakar ruwa

Kayan wanka (baho, shawa)

Sassan FRP na musamman

Jirgin Ruwa Kai Tsaye vs. Haɗin Jirgin Ruwa: Manyan Bambance-bambance

| Ma'auni | Jirgin Ruwa Kai Tsaye | Roving da aka Haɗa |

| Ƙarfi | Ƙarfin juriya mafi girma | Ƙarami kaɗan saboda haɗuwa |

| Ruwan da aka yi da resin | Da sauri, mafi daidaito | Zai iya buƙatar ƙarin resin |

| Saurin Samarwa | Da sauri (mai sauƙin sarrafawa ta atomatik) | Sannu a hankali (tsarin aiki da hannu) |

| farashi | Ƙarancin (ingantaccen samarwa) | Mafi girma (ƙarin sarrafawa) |

| Mafi Kyau Ga | Pultrusion, naɗewar filament | Tsaftace hannu, feshi |

Wanne Ya Kamata Ka Zaɓa?

Lokacin da za a Yi Amfani da Roving Kai Tsaye

✅ Samar da kayayyaki masu yawa (misali, sassan mota)

✅ Aikace-aikace da ke buƙatar ƙarfin gaske (misali, ruwan injin turbine mai iska)

✅ Tsarin kera kayayyaki ta atomatik

Lokacin da za a Yi Amfani da Roving da aka Haɗa

✅ Samar da ƙananan kayayyaki na musamman ko na zamani (misali, gyaran jiragen ruwa)

✅ Hanyoyin ƙera hannu (misali, sassaken FRP na fasaha)

✅ Ayyukan da ke buƙatar sauƙin yankewa da sarrafawa

Yanayin Masana'antu & Hasashen Nan Gaba

Duniyargilashin fiberglassAna hasashen cewa kasuwa za ta girma da kashi 5.8% na CAGR (2024-2030) saboda karuwar buƙata a fannin makamashin iska, rage nauyi a motoci, da kuma kayayyakin more rayuwa. Sabbin abubuwa kamar hawa da sauka da kuma ...

Kammalawa

Zaɓar tsakanin kai tsaye datattaro jiragen ruwaya dogara da hanyar samar da kayanka, kasafin kuɗinka, da buƙatun aiki.Yawo kai tsayeYa yi fice a aikace-aikacen sauri da ƙarfi mai yawa, yayin da aka haɗa roving ya fi kyau don ƙera hannu da hannu.

Kuna buƙatar shawarar ƙwararru? Tuntuɓi mai samar da fiberglass don daidaita nau'in tuƙi da ya dace da aikinku.

Lokacin Saƙo: Mayu-06-2025