Gabatarwa

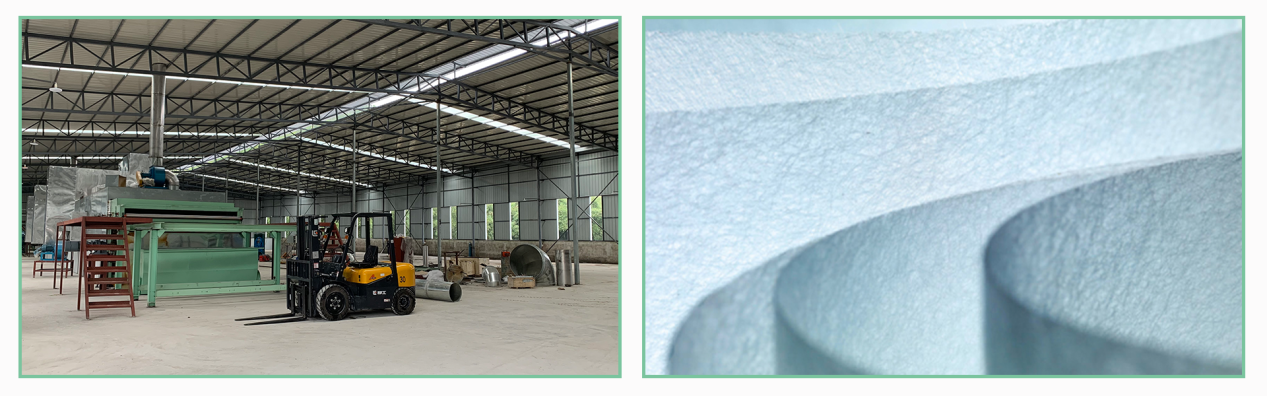

Kayan ƙarfafa fiberglass suna da mahimmanci a cikin kera kayan haɗin gwiwa, suna ba da ƙarfi, juriya, da juriya ga tsatsa. Biyu daga cikin samfuran da aka fi amfani da su sunemat ɗin saman fiberglass kumatabarmar da aka yanka (CSM), kowannensu yana da manufofi daban-daban.

Idan kuna aiki akan aikin fiberglass—ko a fannin ruwa, ko na mota, ko gini—Zaɓar kayan ƙarfafawa da suka dace yana da matuƙar muhimmanci. Wannan labarin yana bincika manyan bambance-bambancen da ke tsakaninmat ɗin saman fiberglass kumatabarmar da aka yanka, kaddarorinsu na musamman, da mafi kyawun aikace-aikacen da zasu taimaka muku yanke shawara mai ma'ana.

Menene Tabarmar Fuskar Fiberglass?

A mat ɗin saman fiberglass (wanda kuma ake kira atabarma mai rufe fuska) sirara ce, wacce ba a saka ba, wadda aka yi da zare-zaren gilashi da aka rarraba bazuwar da aka haɗa ta da manne mai narkewar resin. Ana amfani da ita musamman don:

·Samar da kyakkyawan saman da ya yi santsi, mai wadataccen resin

·Inganta tsatsa da juriya ga sinadarai

·Rage bugawa (ganewar tsarin zare) a cikin sassan da aka shafa da gel

·Inganta mannewa tsakanin yadudduka a cikin laminates

Amfani da Yawa na Tabarmar Fiberglass

·Kwantenan ruwa da bene

·Allon jikin mota

·Ruwan injin turbin iska

·Wuraren ninkaya da tankuna

Menene Tabarmar Zaren da Aka Yanka (CSM)?

A tabarmar da aka yankakke (CSM) ya ƙunshi gajerun zare na gilashi waɗanda aka haɗa su tare da wani abu mai ɗaurewa. tabarmar saman, CSM ya fi kauri kuma yana ba da ƙarfafa tsarin.

Muhimman halaye na CSM:

·Babban rabon ƙarfi-da-nauyi

·Kyakkyawan shan resin (saboda tsarin zare mai laushi)

·Mai sauƙin ƙera siffofi masu rikitarwa

Amfani da Yawa na Tabarmar Zare da Aka Yanka

·Jakunkunan jirgin ruwa da manyan kango

·Baho da wuraren shawa

·Sassan motoci

·Tankunan ajiya na masana'antu

Babban Bambanci: Tabarmar saman Fiberglass da Tabarmar Zaren da aka Yanka

| Fasali | Matatar saman fiberglass | Tabarmar Zaren da Aka Yanka (CSM) |

| Kauri | Sirara sosai (10-50 gsm) | Mai kauri (300-600 gsm) |

| Babban Aikin | Ƙarewa mai santsi, juriya ga lalata | Ƙarfafa tsarin |

| Shan Guduro | Ƙasa (surface mai cike da resin) | Babba (yana buƙatar ƙarin resin) |

| Gudummawar Ƙarfi | Mafi ƙaranci | Babban |

| Aikace-aikace na gama gari | Manyan laminates a cikin zane | Manyan yadudduka a cikin mahaɗan |

1. Ƙarfin Tsarin da Kammalawa a Sama

CSM yana ƙara ƙarfin injiniya kuma ana amfani da shi sau da yawa a cikin tsarin ɗaukar kaya.

Tabarmar saman yana inganta kyawun fuska kuma yana hana zare ta hanyar bugawa.

2. Dacewa da Amfani da Resin

Tabarmar saman buƙatar ƙarancin resin, yana samar da ƙarewa mai santsi, mai rufi da gel.

CSM yana shan ƙarin resin, wanda hakan ya sa ya dace da laminates masu kauri da tauri.

3. Sauƙin Kulawa

Tabarmar saman suna da laushi kuma suna yagewa cikin sauƙi, suna buƙatar kulawa da kyau.

CSM ya fi ƙarfi amma yana iya zama da wahala a daidaita shi da matsewar lanƙwasa.

Lokacin da za a Yi Amfani da Kowane Nau'in Tabarmar

Mafi kyawun Amfani don Matatar Fuskar Fiberglass

✅Matakan ƙarshe a cikin kwale-kwale don kammalawa mai santsi

✅Rufin da ke jure tsatsa a cikin tankunan sinadarai

✅Kayan aikin mota don hana zare ta hanyar bugawa

Mafi kyawun Amfani ga Tabarmar Zaren da Aka Yanka

✅Kwandon jirgin ruwa na gine-gine da bene

✅Sassan da aka ƙera kamar baho da kwanon shawa

✅Gyaran da ke buƙatar laminates masu kauri da ƙarfi

Za ku iya amfani da Tabarmar biyu tare?

Eh! Yawancin ayyukan haɗaka suna amfani da tabarmi biyu a matakai daban-daban:

1.Layer na farko: CSM don ƙarfi

2.Yankunan Tsakiya: Saƙa ko ƙarin CSM

3.Layin Ƙarshe:Tabarmar saman don kammalawa mai santsi

Wannan haɗin yana tabbatar da dorewa da kuma kyakkyawan yanayin aiki.

Kammalawa: Wanne Ya Kamata Ka Zaɓa?

Zaɓimat ɗin saman fiberglass idan kana buƙatar kammalawa mai santsi, mai jure tsatsa.

Zaɓitabarmar da aka yankakke idan ƙarfafa tsarin shine fifikonku.

Haɗa duka biyun don ayyukan da ke buƙatar ƙarfi da kuma kammalawa mai kyau.

Fahimtar waɗannan bambance-bambancen zai taimaka muku zaɓar kayan da suka dace don aikin fiberglass ɗinku, tabbatar da ingantaccen aiki da tsawon rai.

Lokacin Saƙo: Mayu-06-2025