Zaren carbon abu ne mai zare wanda ke da sinadarin carbon fiye da kashi 95%. Yana da kyawawan halaye na injiniya, sinadarai, lantarki da sauran kyawawan halaye. Shi ne "sarkin sabbin kayayyaki" kuma kayan dabaru ne da ba a samu a ci gaban soja da farar hula ba. Wanda aka sani da "Baƙar Zinare".

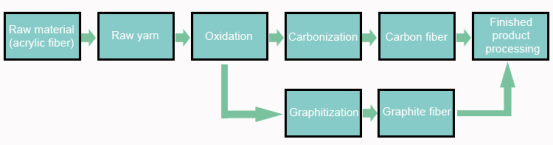

Layin samar da carbon fiber shine kamar haka:

Ta yaya ake yin siririn zaren carbon?

Fasahar samar da sinadarin carbon fiber ta bunƙasa zuwa yanzu kuma ta girma. Tare da ci gaba da haɓaka kayan haɗin fiber carbon, yana ƙara samun karɓuwa daga dukkan fannoni na rayuwa, musamman ci gaban jiragen sama, motoci, layin dogo, ruwan wukake masu amfani da iska, da sauransu da kuma tasirinsa, ci gaban masana'antar fiber carbon. Akwai fa'idodi da yawa.

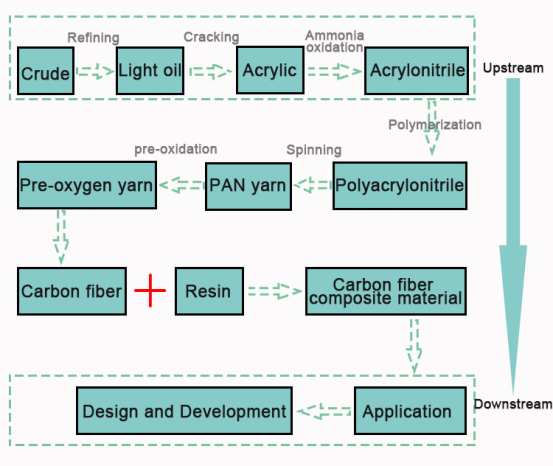

Za a iya raba sarkar masana'antar fiber carbon zuwa sama da ƙasa. Sama yawanci yana nufin samar da kayan da suka shafi fiber carbon; ƙasa yawanci yana nufin samar da kayan aikin fiber carbon. Kamfanoni tsakanin sama da ƙasa na iya ɗaukar su a matsayin masu samar da kayan aiki a cikin tsarin samar da fiber carbon. Kamar yadda aka nuna a cikin hoton:

Duk wani tsari daga siliki mai ɗanɗano zuwa zare mai carbon daga sama zuwa sama na sarkar masana'antar zare mai carbon yana buƙatar a bi shi ta hanyoyi kamar tanderun oxidation, tanderun carbonization, tanderun graphitization, gyaran saman, da kuma girmansa. Tsarin zaren yana da rinjaye ta hanyar zare mai carbon.

Saman sarkar masana'antar zare mai carbon na masana'antar mai ne, kuma acrylonitrile galibi ana samunsa ne ta hanyar tace mai, fashewa, iskar shaka ta ammonia, da sauransu; Ana samun zare mai precursor na Polyacrylonitrile, ana samun zare mai carbon ta hanyar yin oxidizing da kuma canza zare mai precursor, kuma ana samun kayan haɗin zare mai carbon ta hanyar sarrafa zare mai carbon da resin mai inganci don biyan buƙatun aikace-aikace.

Tsarin samar da zare na carbon ya ƙunshi zane, zana zane, daidaita shi, haɗakar carbon, da kuma yin graphitization. Kamar yadda aka nuna a cikin hoton:

Zane:Wannan shine mataki na farko a cikin tsarin samar da zare na carbon. Yakan raba kayan da aka yi amfani da su zuwa zare, wanda hakan canji ne na zahiri. A lokacin wannan tsari, canja wurin taro da zafi tsakanin ruwan da ke juyawa da ruwan coagulation, kuma a ƙarshe ruwan PAN yana hazo. Filaye suna samar da tsarin gel.

Zana:yana buƙatar zafin jiki na digiri 100 zuwa 300 don aiki tare da tasirin shimfiɗa zaruruwa masu daidaitawa. Hakanan muhimmin mataki ne a cikin babban modulus, ƙarfafawa mai ƙarfi, yawan yawa, da kuma inganta zaruruwan PAN.

Kwanciyar hankali:Sarkar macromolecular mai layi na thermoplastic PAN an canza ta zuwa tsarin trapezoidal mara filastik mai jure zafi ta hanyar amfani da hanyar dumama da iskar shaka a digiri 400, ta yadda ba za ta narke ba kuma ba za ta iya ƙonewa ba a babban zafin jiki, tana kiyaye siffar zare, kuma thermodynamics yana cikin yanayi mai kyau.

Samar da iskar carbon:Ya zama dole a fitar da abubuwan da ba su da sinadarin carbon a cikin PAN a zafin jiki na digiri 1,000 zuwa 2,000, sannan a ƙarshe a samar da zare na carbon tare da tsarin turbostratic graphite tare da sinadarin carbon fiye da 90%.

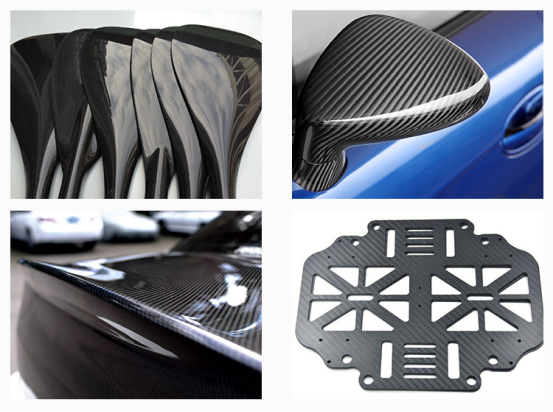

Yadin da aka yi da fiber carbon

Tsarin Zane-zane: Yana buƙatar zafin digiri 2,000 zuwa 3,000 don canza kayan da aka yi da carbon mai siffar amorphous da turbostratic zuwa tsarin graphite mai girma uku, wanda shine babban ma'aunin fasaha don inganta tsarin zaruruwan carbon.

Cikakken tsarin zare na carbon daga tsarin samar da siliki na danye zuwa samfurin da aka gama shine cewa silikin PAN raw ana samar da shi ta hanyar tsarin samar da siliki na danye na baya. Bayan an yi zane da zafin danshi na mai ciyar da waya, ana mayar da shi zuwa tanderun kafin oxidation ta hanyar injin zane. Bayan an gasa shi a yanayin zafi daban-daban a cikin rukunin tanderun kafin oxidation, ana samar da zare na oxidized, wato, zare na oxidized; zare na oxidized ana samar da zare na carbon bayan an ratsa ta cikin tanderun carbonization na matsakaici da zafi mai zafi; sannan zare na carbon ana yin maganin saman, girma, bushewa da sauran hanyoyin don samun samfuran zare na carbon. . Duk tsarin ciyar da waya akai-akai da kuma cikakken iko, ƙaramin matsala a kowace hanya zai shafi samarwa mai dorewa da ingancin samfurin zare na carbon na ƙarshe. Samar da zare na carbon yana da dogon tafiyar tsari, mahimman abubuwan fasaha da yawa, da kuma shingen samarwa mai yawa. Haɗakar fannoni da fasaha da yawa ne.

Abin da ke sama shine ƙera zaren carbon, bari mu kalli yadda ake amfani da yadin zaren carbon!

Sarrafa kayayyakin zane na carbon fiber

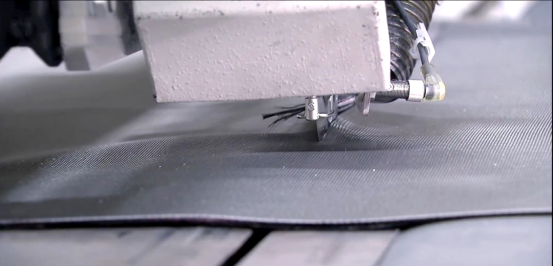

1. Yankewa

Ana fitar da prepreg daga wurin ajiyar sanyi a ƙasa da digiri 18. Bayan farkawa, mataki na farko shine a yanke kayan daidai bisa ga zane na kayan da ke kan injin yankewa ta atomatik.

2. Yin shimfidar wuri

Mataki na biyu shine a shimfiɗa prepreg a kan kayan aikin shimfiɗawa, sannan a shimfiɗa layuka daban-daban bisa ga buƙatun ƙira. Ana gudanar da dukkan ayyuka a ƙarƙashin sanya laser.

3. Ƙirƙira

Ta hanyar robot mai sarrafa kansa, ana aika preform ɗin zuwa injin ƙera don ƙera matsi.

4. Yankewa

Bayan an ƙera, ana aika kayan aikin zuwa wurin aikin robot ɗin yanka don mataki na huɗu na yankewa da cire kayan aikin don tabbatar da daidaiton girman kayan aikin. Hakanan ana iya sarrafa wannan tsari akan CNC.

5. Tsaftacewa

Mataki na biyar shine a yi busasshen tsaftace kankara a wurin tsaftacewa don cire sinadarin sakin iska, wanda ya dace da tsarin shafa manne na gaba.

6. Manne

Mataki na shida shine a shafa manne mai tsari a tashar robot ɗin da ke mannewa. Matsayin mannewa, saurin mannewa, da fitowar manne duk an daidaita su daidai. Wani ɓangare na haɗin da sassan ƙarfe an manne shi da rivet, wanda ake yi a tashar rivet.

7. Duba taro

Bayan an shafa manne, ana haɗa bangarorin ciki da na waje. Bayan an warke manne, ana yin binciken hasken shuɗi don tabbatar da daidaiton girman ramukan maɓalli, maki, layuka, da saman.

Fiber ɗin carbon ya fi wahalar sarrafawa

Zaren carbon yana da ƙarfin juriya na kayan carbon da kuma sauƙin sarrafawa na zaruruwa. Zaren carbon sabon abu ne mai kyawawan halayen injiniya. Misali, mu ɗauki zaren carbon da ƙarfe namu na yau da kullun, ƙarfin zaren carbon yana kusa da 400 zuwa 800 MPa, yayin da ƙarfin ƙarfe na yau da kullun yana tsakanin 200 zuwa 500 MPa. Idan aka duba tauri, zaren carbon da ƙarfe suna kama da juna, kuma babu wani bambanci a bayyane.

Fiber ɗin carbon yana da ƙarfi mafi girma da nauyi mai sauƙi, don haka ana iya kiran fiber ɗin carbon sarkin sabbin kayayyaki. Saboda wannan fa'idar, yayin sarrafa haɗakar da aka ƙarfafa ta hanyar amfani da fiber ɗin carbon (CFRP), matrix da zare suna da hulɗar ciki mai rikitarwa, wanda ke sa halayensu na zahiri ya bambanta da na ƙarfe. Yawan CFRP ya fi na ƙarfe ƙanƙanta, yayin da ƙarfin ya fi yawancin ƙarfe girma. Saboda rashin daidaituwar CFRP, cirewar fiber ko cirewar fiber na matrix sau da yawa yana faruwa yayin sarrafawa; CFRP yana da juriya mai ƙarfi ga zafi kuma yana sa juriya, wanda ke sa ya fi wahala ga kayan aiki yayin sarrafawa, don haka ana samar da babban adadin zafi na yankewa a cikin tsarin samarwa, wanda ya fi tsanani ga lalacewar kayan aiki.

A lokaci guda kuma, tare da ci gaba da faɗaɗa filayen aikace-aikacensa, buƙatun suna ƙara zama masu sauƙi, kuma buƙatun amfani da kayan aiki da buƙatun inganci na CFRP suna ƙara zama masu tsauri, wanda hakan ke haifar da hauhawar farashin sarrafawa.

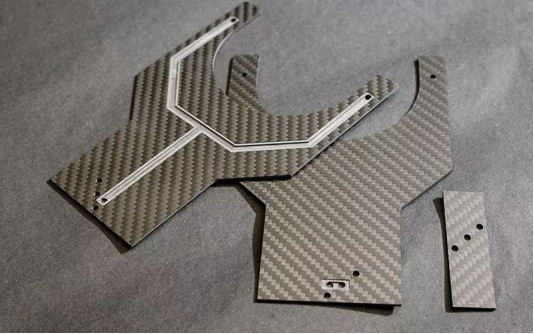

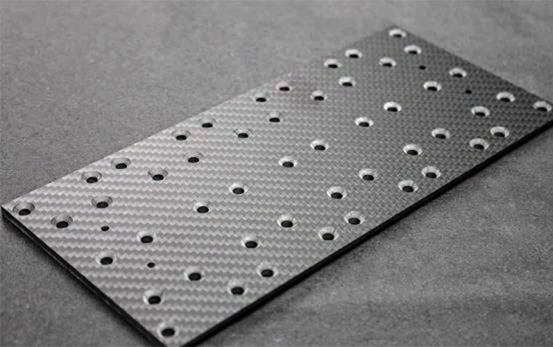

Sarrafa allon fiber na carbon

Bayan an wartsake kuma an samar da allon zare na carbon, ana buƙatar yin aiki bayan an gama aiki kamar yankewa da haƙa rami don buƙatun daidaito ko buƙatun haɗawa. A ƙarƙashin yanayi iri ɗaya kamar sigogin aikin yankewa da zurfin yankewa, zaɓar kayan aiki da haƙa rami na kayan aiki, girma da siffofi daban-daban za su sami tasiri daban-daban. A lokaci guda, abubuwa kamar ƙarfi, alkibla, lokaci, da zafin kayan aikin da haƙa ramin suma za su shafi sakamakon aikin.

A cikin tsarin bayan sarrafawa, yi ƙoƙarin zaɓar kayan aiki mai kaifi mai rufin lu'u-lu'u da kuma injin haƙa mai ƙarfi. Juriyar lalacewa na kayan aikin da injin haƙa da kansa yana ƙayyade ingancin sarrafawa da tsawon lokacin aikin. Idan kayan aikin da injin haƙa ba su da kaifi sosai ko kuma an yi amfani da su ba daidai ba, ba wai kawai zai hanzarta lalacewa da tsagewa ba, zai ƙara farashin sarrafa samfurin, har ma zai haifar da lalacewa ga farantin, yana shafar siffar da girman farantin da kwanciyar hankali na girman ramuka da ramuka a kan farantin. Yana haifar da tsagewar kayan, ko ma rugujewar tubalan, wanda ke haifar da wargajewar allon gaba ɗaya.

Lokacin haƙa ramitakardar fiber carbon, saurin gudu, mafi kyawun sakamako. A cikin zaɓin ramukan haƙa rami, ƙirar musamman ta gefen fuska ta PCD8 ta fi dacewa da zanen fiber na carbon, wanda zai iya ratsa zanen fiber na carbon mafi kyau kuma ya rage haɗarin wargajewa.

Lokacin yanke kauri zanen fiber na carbon, ana ba da shawarar amfani da na'urar yanka matsewa mai kaifi biyu tare da ƙirar gefen hagu da dama na helical. Wannan gefen yankewa mai kaifi yana da saman da ƙananan ƙarshen helical don daidaita ƙarfin axial na kayan aikin sama da ƙasa yayin yankewa, don tabbatar da cewa ƙarfin yankewa da aka samu ya kai ga ɓangaren ciki na kayan, don samun yanayin yankewa mai ɗorewa da kuma hana faruwar ɓarnar kayan. Tsarin gefuna na sama da ƙasa na na'urar "Pineapple Edge" kuma yana iya yanke zanen fiber na carbon yadda ya kamata. Babban sarewarsa na chip zai iya ɗauke zafi mai yawa ta hanyar fitar da chips yayin aikin yankewa, don guje wa lalacewar halayen takardar fiber na carbon.

01 Zaren zare mai ci gaba

Siffofin samfurin:Mafi yawan nau'ikan samfuran da masana'antun zare na carbon suka fi amfani da su, kunshin ya ƙunshi dubban monofilaments, waɗanda aka raba zuwa nau'i uku bisa ga hanyar karkatarwa: NT (Never Twisted, untwisted), UT (Untwisted, untwisted), TT ko ST (Twisted, twisted), wanda NT shine mafi yawan amfani da zare na carbon.

Babban aikace-aikacen:Ana amfani da shi galibi don kayan haɗin gwiwa kamar CFRP, CFRTP ko kayan haɗin gwiwa na C/C, kuma filayen aikace-aikacen sun haɗa da kayan aikin jirgin sama/aerospace, kayan wasanni da sassan kayan aikin masana'antu.

02 Zaren Zare Mai Tsauri

Siffofin samfurin:Zaren zare mai gajere ga gajere, zaren da aka yi da gajerun zaren carbon, kamar zaren carbon mai amfani da manufa ta gabaɗaya, yawanci samfura ne a cikin nau'in zaren gajere.

Babban amfani:kayan hana gogayya, kayan hana gogayya, sassan hadewar C/C, da sauransu.

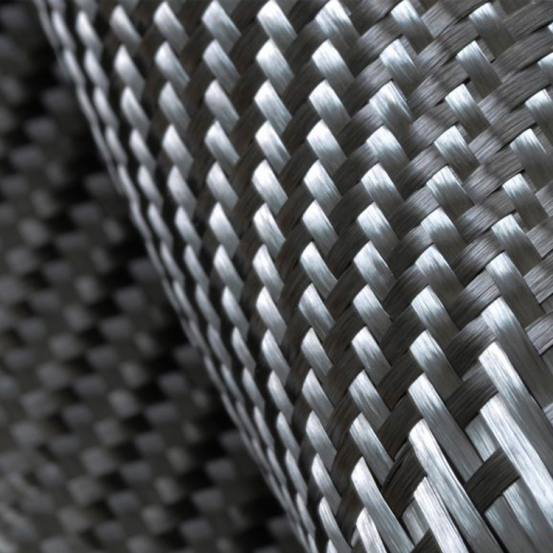

03 Yadin Carbon Fiber

Siffofin samfurin:An yi shi ne da zaren carbon mai ci gaba ko zaren carbon fiber mai juyawa. Dangane da hanyar saka, ana iya raba zaren carbon fiber zuwa yadi mai saka, yadi mai saka da kuma yadi mara saka. A halin yanzu, yadi mai saka carbon yawanci yadi ne da aka saka.

Babban aikace-aikacen:Kamar yadda ake amfani da zare mai ci gaba da carbon, wanda galibi ake amfani da shi a cikin kayan haɗin gwiwa kamar CFRP, CFRTP ko kayan haɗin gwiwa na C/C, kuma fannonin aikace-aikacen sun haɗa da kayan aikin jirgin sama/aerospace, kayan wasanni da sassan kayan aikin masana'antu.

04 Belin da aka haɗa da Carbon Fiber

Siffofin samfurin:Yana cikin wani nau'in masana'anta na carbon fiber, wanda kuma aka saka shi da zaren carbon mai ci gaba ko zaren carbon fiber mai juyawa.

Babban amfani:Ana amfani da shi galibi don kayan ƙarfafawa na tushen resin, musamman don samarwa da sarrafa samfuran bututu.

05 Zaren carbon da aka yanka

Siffofin samfurin:Sabanin ra'ayin zaren da aka yi da zaren carbon fiber, yawanci ana shirya shi ne daga zaren carbon mai ci gaba ta hanyar sarrafa shi da aka yanka, kuma ana iya yanke tsawon zaren bisa ga buƙatun abokin ciniki.

Babban amfani:Yawanci ana amfani da shi azaman cakuda robobi, resins, siminti, da sauransu, ta hanyar haɗawa cikin matrix, ana iya inganta halayen injiniya, juriyar lalacewa, ikon wutar lantarki da juriyar zafi; a cikin 'yan shekarun nan, zaruruwan ƙarfafawa a cikin abubuwan haɗin fiber na carbon na bugawa na 3D galibi sune zaruruwan carbon da aka yanka. babban.

06 Nika fiber na carbon

Siffofin samfurin:Tunda zaren carbon abu ne mai karyewa, ana iya shirya shi ya zama foda na zaren carbon bayan niƙa, wato, niƙa zaren carbon.

Babban aikace-aikacen:kama da yankakken zaren carbon, amma ba kasafai ake amfani da shi ba wajen ƙarfafa siminti; yawanci ana amfani da shi azaman mahaɗin filastik, resin, roba, da sauransu don inganta halayen injiniya, juriyar lalacewa, watsa wutar lantarki da juriyar zafi na matrix.

07 Tabarmar fiber carbon

Siffofin samfurin:Babban siffar ita ce ji ko tabarma. Da farko, ana yin layukan gajerun zare ta hanyar amfani da na'urar buga takardu da sauran hanyoyi, sannan a shirya su ta hanyar huda allura; wanda kuma aka sani da masana'anta mara saƙa ta carbon fiber, tana cikin wani nau'in masana'anta da aka saka ta carbon fiber.Babban amfani:kayan rufi na zafi, kayan rufi na zafi da aka ƙera, yadudduka masu kariya masu jure zafi da kuma kayan rufi masu jure tsatsa, da sauransu.

08 Takardar fiber ta carbon

Siffofin samfurin:Ana shirya shi daga zare na carbon ta hanyar busasshiyar hanyar yin takarda ko takarda mai laushi.

Babban amfani:faranti masu hana tsayawa, electrodes, lasifika masu lasifika da faranti masu dumama; aikace-aikacen zafi a cikin 'yan shekarun nan sabbin kayan cathode na batirin motar makamashi ne, da sauransu.

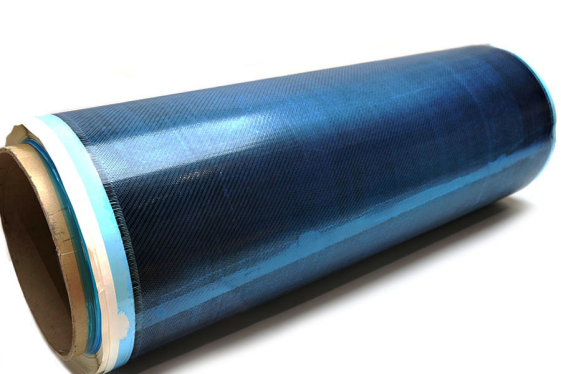

09 Shirye-shiryen fiber na carbon

Siffofin samfurin:wani abu mai matsakaicin matsakaici wanda aka yi da resin thermosetting na carbon fiber, wanda ke da kyawawan halaye na injiniya kuma ana amfani da shi sosai; faɗin prepreg na carbon fiber ya dogara da girman kayan aikin sarrafawa, kuma ƙayyadaddun bayanai na yau da kullun sun haɗa da kayan prepreg na 300mm, 600mm, da 1000mm.

Babban aikace-aikacen:kayan aikin jirgin sama/samar da sararin samaniya, kayan wasanni da kayan aikin masana'antu, da sauransu.

010 kayan haɗin fiber carbon

Siffofin samfurin:Ana yin allurar da aka yi da thermoplastic ko thermosetting resin da aka haɗa da carbon fiber, ana ƙara cakuda da ƙarin abubuwa daban-daban da yankakken zare, sannan a yi amfani da tsarin haɗa su.

Babban aikace-aikacen:Dangane da kyakkyawan yanayin wutar lantarki na kayan, ƙarfin juriya da fa'idodin sauƙi, ana amfani da shi galibi a cikin akwatunan kayan aiki da sauran kayayyaki.

Muna kuma samarwafiberglass direct roving,tabarmar fiberglass, ragar fiberglass, kumarufin fiberglass da aka saka.

Tuntube mu:

Lambar waya:+8615823184699

Lambar waya: +8602367853804

Email:marketing@frp-cqdj.com

Lokacin Saƙo: Yuni-01-2022