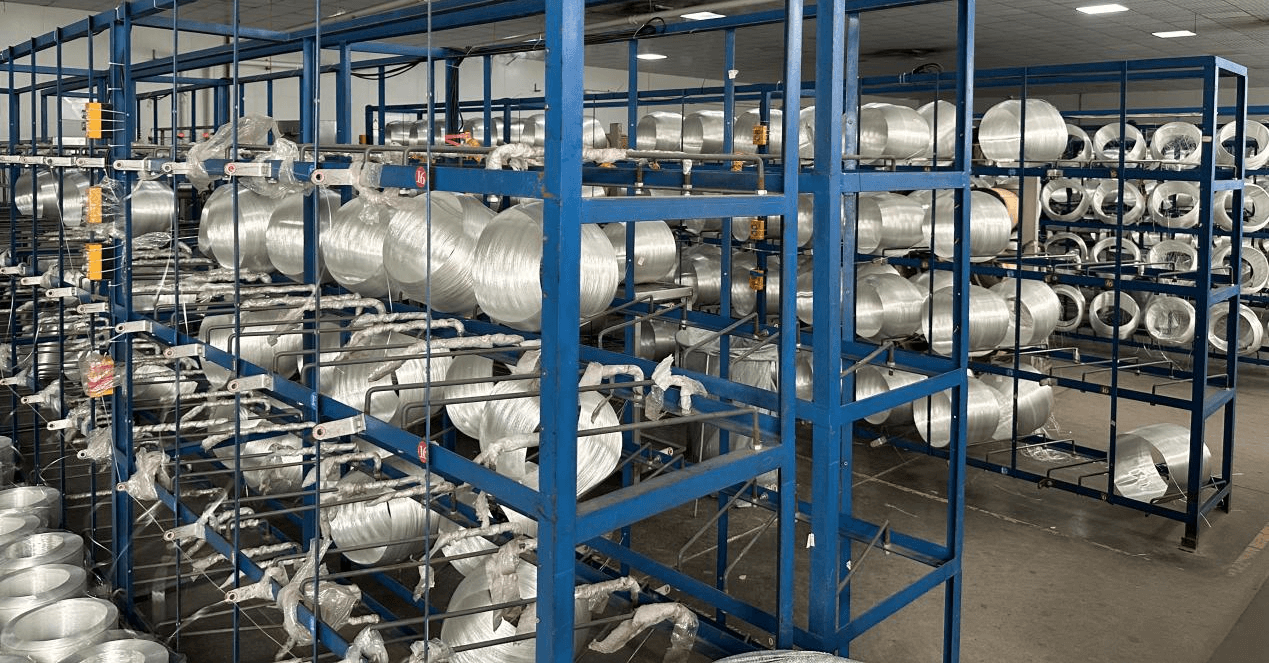

A duniyar masana'antu masu haɗaka, ana kashe makudan kuɗi wajen inganta sinadaran resin, daidaita saurin pultrusion, da kuma daidaita rabon fiber-to-resin. Duk da haka, sau da yawa ana yin watsi da wani muhimmin abu har sai layin samarwa ya tsaya ko kuma tarin sassan da aka gama sun faɗi gwajin damuwa:yanayin ajiya nagilashin fiberglass.

Fiberglass rovingba abu ne mai aiki ba. Abu ne mai matuƙar inganci wanda aka lulluɓe shi da wani sinadari mai sarkakiya wanda ke aiki a matsayin haɗin gwiwa tsakanin gilashin da ba shi da aiki da kuma resin halitta. Wannan sinadari yana da matuƙar tasiri, kuma lalacewarsa yayin ajiya na iya haifar da mummunan gazawa a cikin ingancin tsarin.

A cikin wannan jagorar, mun bincika yadda yanayin zafi, danshi, da kuma hanyoyin adanawa na zahiri ke nuna aikin kayan ƙarfafa ku.

Maƙiyin da Ba a Gani Ba: Danshi da Ruwan Sama

Babban barazana ga adanawagilashin fiberglassdanshi ne. Zaren gilashi a zahiri yana da ruwa (yana jan hankali da ruwa). Duk da cewa zaren gilashin kansu suna da ɗorewa,tsarin girma—gadar sinadarai da ke ba da damar resin ya “jike” ya kuma haɗu da zare—yana da sauƙin kamuwa da shihydrolysis.

Yaushezaren gilashiyawoana adana shi a cikin yanayi mai zafi sosai:

Rage Girman Girma:Danshi yana karya alaƙar sinadarai a cikin girman, wanda hakan ke sa shi ƙasa da tasiri wajen haɓaka mannewa.

Rashin Dakatarwar Ruwa:A lokacin samarwa, resin ɗin bai shiga cikin tarin zare gaba ɗaya ba, wanda ke haifar da "bushewar tabo" da kuma gurɓatattun abubuwa a cikin haɗin ƙarshe.

Aikin Capillary:Idan ƙarshen bobbins ɗin ya bayyana, ana iya jawo danshi cikin marufin ta hanyar aikin capillary, wanda ke haifar da rashin daidaituwa a cikin dukkan naɗin.

Sauye-sauyen Zafin Jiki da Girman Shigowa

Duk da yakezaren gilashiyana da juriya mai yawa ga zafi, girman halitta ba ya da shi. Idan rumbun ajiya yana fuskantar zafi mai tsanani (sama da 35°C/95°F), wani abu da aka sani dagirman ƙauraZai iya faruwa. Rufin sinadarai na iya zama mai motsi kaɗan, yana taruwa a ƙasan bobbin ko kuma yana haifar da "wurare masu mannewa."

Akasin haka, adanawa a cikin yanayin sanyi sannan nan da nan a mayar da shi zuwa wurin samar da ɗumi yana haifar da hakan.danshiWannan tarin danshi mai sauri a saman zare shine babban abin da ke haifar da wargajewa a cikin bututun da ke da rauni a cikin filaye da tasoshin matsin lamba.

Kwatanta: Mafi kyau ko kuma Yanayin Ajiya mara inganci

Domin taimakawa ƙungiyar kula da inganci ta duba wuraren aikin ku, duba teburin da ke ƙasa don ganin ma'aunin masana'antu.

Ka'idojin Ajiyar Fiberglass Roving

| Sigogi | Mafi kyawun Yanayi (Mafi kyawun Aiki) | Yanayin da ba shi da inganci (Babban Haɗari) | Tasiri akan Aiki |

| Zafin jiki | 5°C zuwa 35°C (Tsawon lokaci) | Ƙasa da 0°C ko Sama da 40°C | Girman ƙaura, zaruruwa masu rauni, ko kuma danshi. |

| Danshin Dangi | 35% zuwa 65% | Sama da kashi 75% | Haɗakar da sinadarin hydrolysis, rashin kyawun haɗin resin-to-fiber. |

| Sauya al'ada | Awanni 24-48 a cikin bitar kafin amfani. | Amfani kai tsaye daga wurin ajiyar sanyi. | Ƙananan fasa a cikin matrix na resin saboda danshi. |

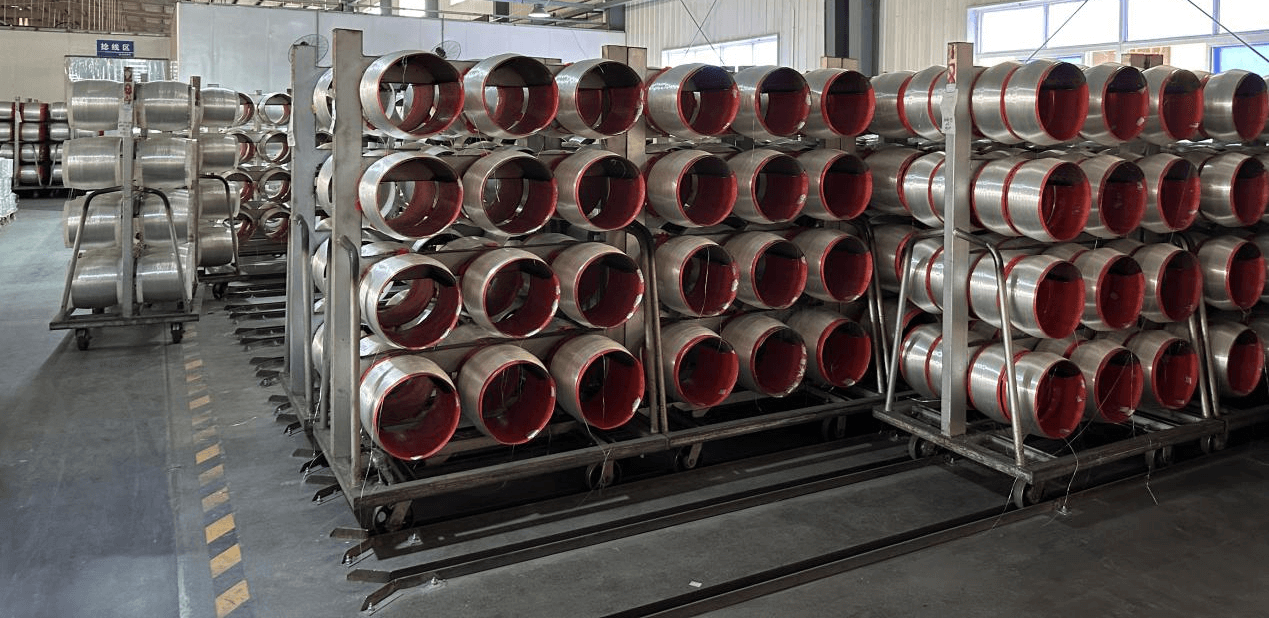

| Tarawa | Pallets na asali; matsakaicin tsayi 2 (idan an tsara shi). | Bobbins masu santsi; tsayin da ya wuce kima. | Nakasar jiki ta bobbins; matsalolin tashin hankali. |

| Fuskar Haske | Muhalli mai duhu ko ƙarancin UV. | Hasken rana kai tsaye (kusa da tagogi). | Lalacewar UV na marufi da sinadarai masu girma. |

Ingancin Jiki: Matsalolin Tarawa da Tashin Hankali

Fiberglass rovingyawanci ana ɗaure shi a kan bobbins tare da madaidaicin matsin lamba. Idan an adana waɗannan bobbins ɗin ba daidai ba - kamar a ajiye su a kwance ba tare da tallafi ba ko kuma a niƙa su a ƙarƙashin nauyi mai yawa - yanayin ciki na kunshin yana canzawa.

Bambancin Tashin Hankali:Bobbins ɗin da aka niƙa suna haifar da rashin daidaituwar "biya" yayin pultrusion ko naɗewar filament. Wannan yana haifar da wasu zaruruwa su fi wasu ƙarfi, suna haifar da damuwa ta ciki a ɓangaren da aka gama wanda zai iya haifar da karkacewa ko gazawar da wuri.

Fuzz da Karyewa:Idan aka yi karo ko aka jawo bobbins a kan benaye masu tsauri na rumbun ajiya, saman gilashin ya lalace. Waɗannan zare-zaren da suka karye suna haifar da "fuzz" a layin samarwa, wanda zai iya toshe jagororin kuma ya gurɓata bandakin resin.

Matsayin Marufi: Dalilin da yasa "Asalin" ya fi kyau

Fiberglass roving mai inganciYawanci ana kawo shi a cikin naɗaɗɗen na'urar sanyaya iska ta UV tare da fakitin busarwa. Kuskure da aka saba gani a wuraren ƙera kayan shine cire wannan marufin da wuri.

Nau'in asali yana da muhimman ayyuka guda uku:

Shamakin Danshi:Yana aiki a matsayin babban kariya daga danshi na yanayi.

Rigakafin Kura:Ƙwayoyin halitta (ƙura, sawdust, ko aski na ƙarfe) daga masana'anta na iya kawo cikas ga haɗin sinadarai tsakanin gilashin da resin.

Ma'aunin:Yana hana yin tafiya daga "sloughing" ko faɗuwa daga bobbin yayin sarrafawa.

Hanyoyi 5 Mafi Kyau Don Kula da Ingancin Yin Mota a Kan Titin Jirgin Ruwa

Domin tabbatar da cewa kayanka suna aiki kamar yadda masana'anta suka ƙayyade, aiwatar da waɗannan ƙa'idodi guda biyar na rumbun ajiya:

Farko-Shiga, Farko-Shiga (FIFO): Fiberglass rovingyana da tsawon lokacin shiryawa, yawanci watanni 6 zuwa 12. Tabbatar an fara amfani da tsofaffin kayan abinci don hana tsufan girman.

Dokar Sa'o'i 24:Kullum a kawo na'urorin jigilar kaya daga rumbun ajiya zuwa ɗakin samarwa aƙalla awanni 24 kafin amfani. Wannan yana ba kayan damar isa ga "daidaitaccen yanayin zafi," yana hana danshi lokacin da aka buɗe kunshin.

Ajiya Mai Girma:Kada a taɓa ajiye fale-falen hawa kai tsaye a kan ƙasan siminti, wanda zai iya “shake” danshi. Yi amfani da fale-falen katako ko fale-falen katako.

Hatimin Bangaren Bobbins:Idan bobbin ɗin rabin amfani ne kawai, kada a bar shi a rufe a kan injin. A sake naɗe shi da filastik kafin a mayar da shi wurin ajiya.

Na'urar aunawa tare da na'urar aunawa (Hygrometers):Sanya na'urorin auna zafin jiki da danshi na dijital a wuraren ajiyar ku. Wannan bayanin yana da matuƙar amfani idan aka gano ƙaruwar lahani a fannin samarwa.

Kammalawa: Kare Zuba Jarinka

Fiberglass rovingabu ne mai matuƙar aiki, amma aikinsa yana da rauni har sai ya warke a cikin matrix na resin. Ta hanyar kula da yanayin ajiya daidai da matakin bincike kamar sigogin masana'antar ku, zaku iya rage yawan tarkace sosai, inganta daidaiton sassan, da kuma tabbatar da dorewar samfuran haɗin ku na dogon lokaci.

Chongqing Dujiang Composites Co., Ltd.

Tuntube Mu:

Yanar gizo: www.frp-cqdj.com/www.cqfiberglass.com/www.cqfrp.ru/www.cqdjfrp.com

Imel:info@cqfiberglass.com/marketing@frp-cqdj.com /marketing01@frp-cqdj.com

WhatsApp:+8615823184699

Tel:+86-023-67853804

Lokacin Saƙo: Janairu-09-2026